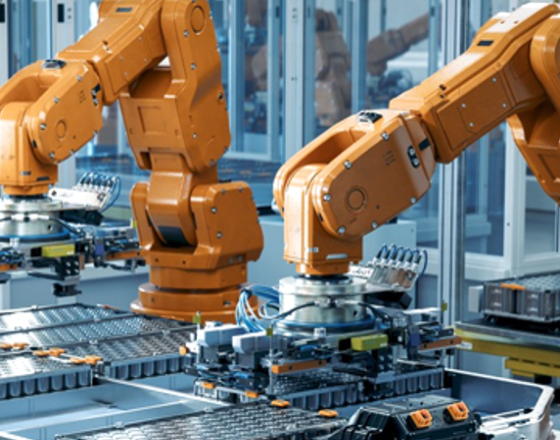

Bearings in automation equipment are crucial for reducing friction and ensuring smooth, precise movement of mechanical components. They support rotating parts like shafts, motors, and conveyor systems, enabling efficient and reliable operation. Bearings handle both radial and axial loads, maintaining accurate alignment and minimizing wear. In robotic arms and assembly lines, bearings improve speed, precision, and stability, enhancing the overall performance of automation systems. High-quality bearings contribute to reduced maintenance needs, increased productivity, and extended equipment lifespan.